NanoSpin 20

📄 Brief Description

The NanoSpin 20 (Multi-Pump Lab-Scale Electrospinning Machine) is engineered for controlled, multi-material nanofiber fabrication using three or more polymer solutions. 🧪 With three independent syringe pumps, it enables simultaneous electrospinning or electro-spraying, producing composite or blended nanofibers with customizable properties.

This versatile system supports both electrospinning and electro-spraying, making it ideal for tissue engineering, drug delivery, filtration, and other advanced applications. All process parameters—including injection rate, spinning distance, collector drum speed, temperature, and humidity—are controlled via a 7” touchscreen panel for precision and ease of use. Compared to the single-pump model, this unit offers three times the production rate while maintaining precise control over multiple materials.

🎯 Applications

The NanoSpin 20 supports both electrospinning and electro-spraying, making it ideal for advanced material synthesis. For instance, a polymeric base can be electrospun from one pump while an additive, such as a drug, is introduced via electro-spraying from another.

🩹 Tissue Engineering – Composite scaffolds and biomedical materials.

💊 Drug Delivery – Multi-material fibers with active pharmaceutical ingredients.

🌬️ Filtration Media – High-performance air and liquid filters.

⚗️ Advanced Material Synthesis – Functional nanofibers with tailored properties.

🔬 Biological & Pharmaceutical Research – Coatings, membranes, and experimental materials.

Syringe pump injection rate

Number of syringes

Output Voltage

Spinning distance

⭐ Main Features

🛡️ Advanced Safety Features – Protects both user and system.

🧩 Modular Design – Flexible setup for various applications.

📺 7” Touchscreen HMI – Simple control of all process parameters.

🛑 Emergency Stop – Immediate system shutdown for safety.

🧪 User-Friendly Operation – Minimal maintenance, quick setup.

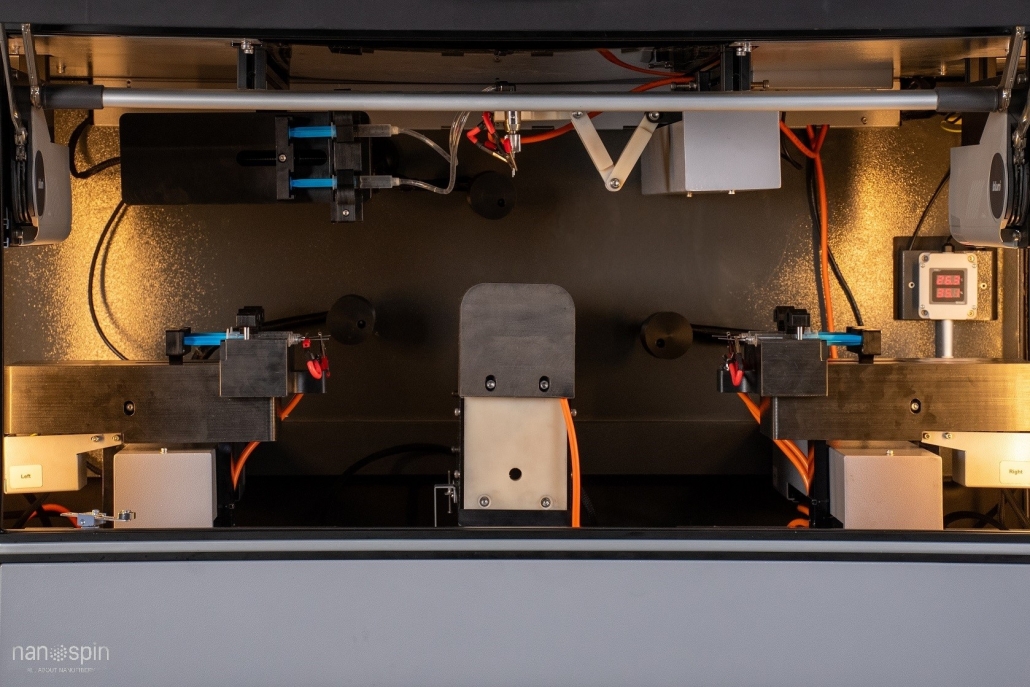

💉 Multi-Syringe Pump System – 3 pumps (2+1), supporting up to 6 syringes (4+2).

↔️ Multiple Scanning Systems – 3 (2+1) scan units with emitters on both sides of the collector.

📏 Adjustable Distance Mechanism – 3 (2+1) distance adjusters for precise emitter positioning.

💧 Minimal Dead Volume – Two direct-injection pumps and one low-dead-volume pump.

⚡ High Voltage System – Three supplies: 2 positive and 1 negative polarity.

🌀 Customizable Collectors – Compatible with multiple collector types.

🔴 2 + 1 Red Lasers – Visual monitoring of nanofiber jets.

🧵 Core-Shell Capability – Coaxial nozzle for core–shell nanofiber production.

🌡️ Optional Atmospheric Control – Regulates temperature and humidity when needed.

Specification

General

General Configuration

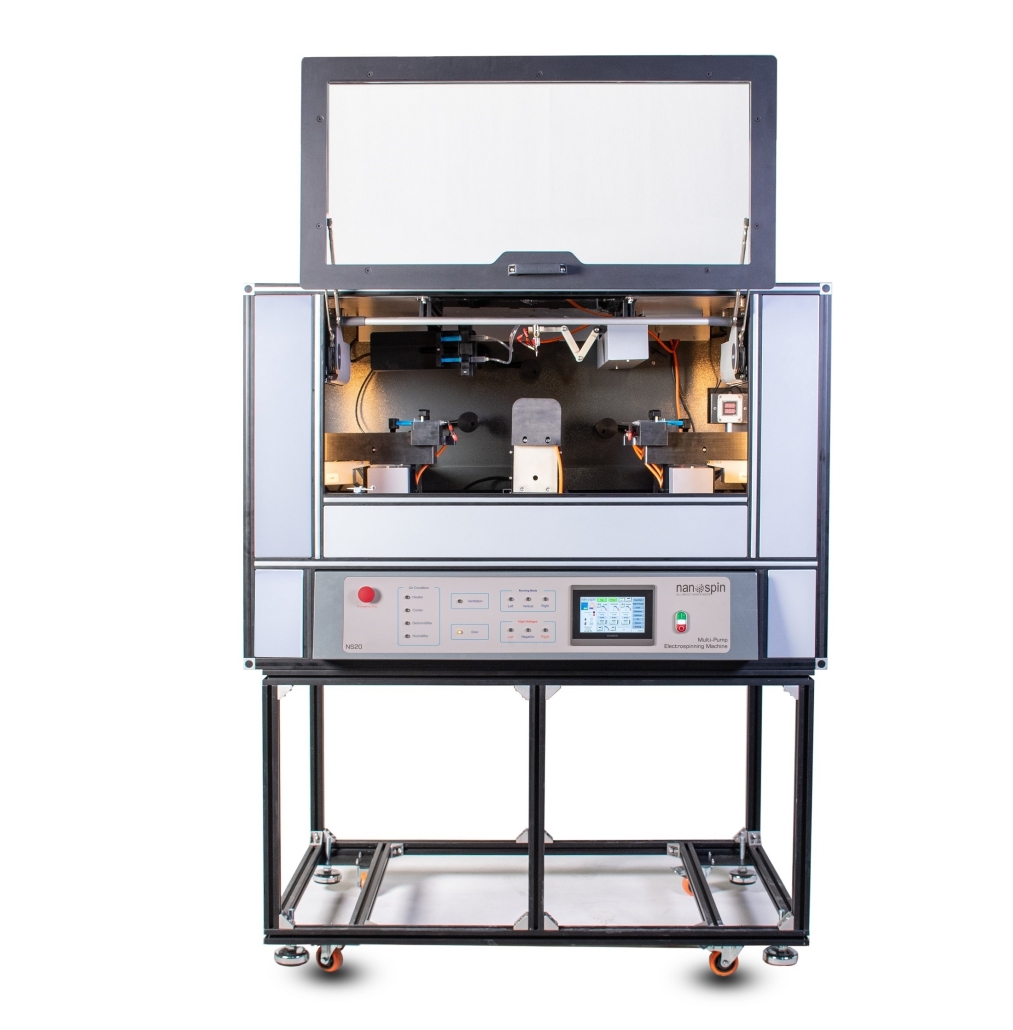

- Chassis: Metallic body with aluminum frames, mounted on wheels

- Lighting: Diffuse LED lighting

- Input Power: 100-240 V AC, 50-60 Hz

- Safety: Automatic voltage cut-off when the door is opened

- Observation System: Optional digital camera for real-time monitoring

- 2 Red Lasers to observe the nanofibers jets

- Dimensions (L×W×H): 155 cm × 100 cm × 110 cm

- Weight: 225 kg

Main Control

Main Control & User Interface

- HMI System: 7” touchscreen interface

- Control System: Programmable Logic Controller (PLC)

- Adjustable Parameters:

- Start and end position of nozzle(s)

- Injection rate of syringe pump(s)

- Electrospinning distance(s)

- Electrospinning duration

- ON/OFF timer for exhaust fan

- Rotational speed control of collector

- Temperature and humidity control

- Alarm notifications for volume thresholds and empty syringe detection

Spinneret

Syringe Pump System

- Number of Syringe Pumps:

- Standard: 2

- Optional: 3rd syringe pump

- Number of Syringes: Up to 6

- Configuration:

- Horizontal alignment (no need for hose)

- Parallel to the collector

- Optional third syringe positioned vertically above the collector (hose required)

- Syringe Pump Injection Rate: 10 µl/h to 500 ml/h

- Usable Syringe Sizes: 1-25 mm (inner diameter)

Scanning System

- Scanning Rate: 0-30 mm/s (adjustable)

- Scanning Range: 0-30 cm (adjustable)

High voltage power supply

High voltage power supply

- Model: PS35 Positive & PS35 Negative

- Max. Output Voltage: 35 kV

- Power Consumption: 30 W

- Voltage Monitoring: Digital display, accuracy: 0.1 kV

- Connections:

- Two positive high-voltage power supplies linked to syringe pumps

- One negative high-voltage power supply linked to the collector

Collector

Specifications

- Negative cylinder & plate collector

- Optional collectors: Wire, mandrel, single wire, radial, needle, and disk collectors

- Material: Stainless steel

- Rotational speed: 300–3000 rpm (cylindrical drum)

- Spinning distance: 5–20 cm

- Nanofiber coverage area: 30 cm × 29 cm (Cylindrical drum)

Collector Dimensions

- Negative Cylindrical Collector: 10 cm (ø) × 29 cm (L)

- Plate Collector: 30 cm × 30 cm

- Single Wire Collector (Optional): Tensioned cable (20+ µm cables)

- Needle Collector (Optional): Replaceable needle

- Disk Collector (Optional): Diameter: 3, 5, & 10 cm

- Wheel Collector (Optional): Diameter: 20 cm, Thickness: 1, 2, & 4 cm

- Mandrel (Optional): Length: 25 cm, Diameter: 2, 4, 6, 8, & 10 mm

All collectors can be attached to a negative high-voltage power supply (-35 kV)

Atmospheric condition

Ventilation

- Programmable fan, adjustable via HMI panel

Atmospheric Control System (Optional)

- Heating system: Adjustable up to 45°C (±1°C)

- Cooling system: Temperature reduction down to 19°C (±1°C)

- Humidifier: Up to 80%

- Dehumidifier: Down to 15% (±5%)

Environmental Requirements

- Operating temperature: 20–30°C

- Operating humidity: 20–70%

Get in touch

Feel free to contact us through phone, email, or social media networks.

Nanospin Ltd.

Company office address

Moondarra, Gorsethorn Way

Fairlight, East Sussex

TN35 4BQ

UK

Contact

Mo-Fr: 9:00-18:00